Home Appliance Plastic Molding refers to washing machine control anel plastic mould, washing machine tub mould and its plastic accessories, air condition frame Plastic Injection Mould and its plastic accessories, ice box or Refrigerator Plastic Injection Mould and its plastic accessories, and so on.

Mould Steel: 2738HH, NAK80, 738, 2344, S136, SDK61, P20, PX5 etc.

Material: PP

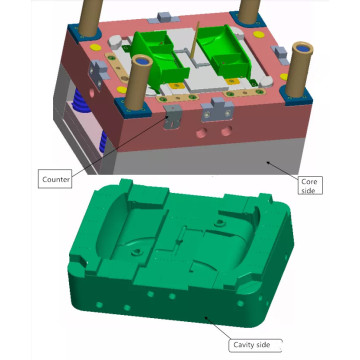

Cavity: 1*1

Applicable range: Home appliance

Lead Time: 35-45 days

Hot runner: (according to the customer's request and product style)

Standard part: PUNCH, MISUMI

First trial equipment: 380T Injection Machine( moreover we also have 90-700T, 750-1300T Injection Machine. There are robots for each 90-380T Injection Machine to meet the customer's bulk production requirement. The first mould tryout success rate is above 90%

The profile: 2D/3D drawing or samples

Manager: Concentrate on project tracking and after service

Engineer: 30-50 excellent engineers, who have many years experience and English communicating well.

The purchase department use EPR system to make sure buying materials in time.

70-130 experienced workers can meet your request of batch production.

Quality department: 15 members quality control workers, testing the mould and parts by CMM and projector.

Shipping incoterms: FOB/CIF/DDU by sea shipping or air shipping