Payment Type:L/C,T/T,D/P,D/A,Paypal

Incoterm:FOB,CFR,CIF,FCA,EXW,FAS,CPT,CIP,DEQ,DDP,DDU,Express Delivery,DAF,DES

Min. Order:1 Set/Sets

Transportation:Ocean,Air,Land,Express

Port:Ningbo,Shanghai,Shenzhen

$3000≥1Set/Sets

Model No.: CT-10880

Brand: Ceeto

Place Of Origin: China

Forming Method: Plastic Injection Mould

Shaping Mode: Injection Mould

Surface Finish Process: Heat Treatment

Mould Cavity: Single Cavity

Plastic Material: ABS

Process Combination Type: Single-Process Mode

Application: Home Use

Runner: Hot Runner

Design Software: UG

Installation: Fixed

Certification: ISO

Standard: DME

Customized: Customized

Product Material: Plastic

Product: Household Product

Packaging: Wooden box

Productivity: 500000shots/mold life

Transportation: Ocean,Air,Land,Express

Place of Origin: China

Supply Ability: 30sets/month

Certificate: ISO

HS Code: 8480790090

Port: Ningbo,Shanghai,Shenzhen

Payment Type: L/C,T/T,D/P,D/A,Paypal

Incoterm: FOB,CFR,CIF,FCA,EXW,FAS,CPT,CIP,DEQ,DDP,DDU,Express Delivery,DAF,DES

Ceeto Mold has rich experience to design high quality plastic injection molds, our company service scope refers to Plastic Injection Mould, Injection Molding Automotive Parts including Automotive Interior Plastic Injection Mould and Automotive Exterior Plastic Injection Mould. As well as Home Appliance Injection Mould, Daily Commodity Injection Mould etc.

Ceeto Molding Company provides customer with high quality plastic fan blade injection moulds which are very common to be used to produce all kinds of plastic fan blade products and airflow ventilator fan products. Fan blade product is widely applied in indoor and outdoor Air conditioner, automotive fan, and household table fan and any other types of fans in our daily lifes. Basically we design and manufacture Plastic Fan Blade mould according to your 2D and 3D fan blade product, you review and approve plastic fan blade mould design, at the same time, we submit you moldflow analysis report, DFM report and mould assembly drawing and mould 3D drawing.

Plastic Fan Blade Injection Mould Technical Description

The key point for plastic fan blade is how to keep dynamic balance, so machining precision is very important, draft angle must be well considered in order to have good demoulding according to shrinkage rate of plastic material that you specified during mould design stage. Wall thickness is not even due to fan blade structure, mould design engineer should consider well not to design push pins on the mould.

Reinforcement ribs must be well considered to design in plastic fan blade mould, hub core is designed solid type as follows:

This kind of moul design concept is better to guarantee fan blade to be in the center when assembly a fan, and more over it's easier for plastic fan blade mould to do the heat treatment. Solid hub core has the following advantages:

Plastic fan blade injection mould gate design is very important for melt plastic to keep filling the balance of product, direct gate is our first consideration. It can go fast and flow even to avoid welding line evidence.

Our processing for making plastic fan blade injection mould

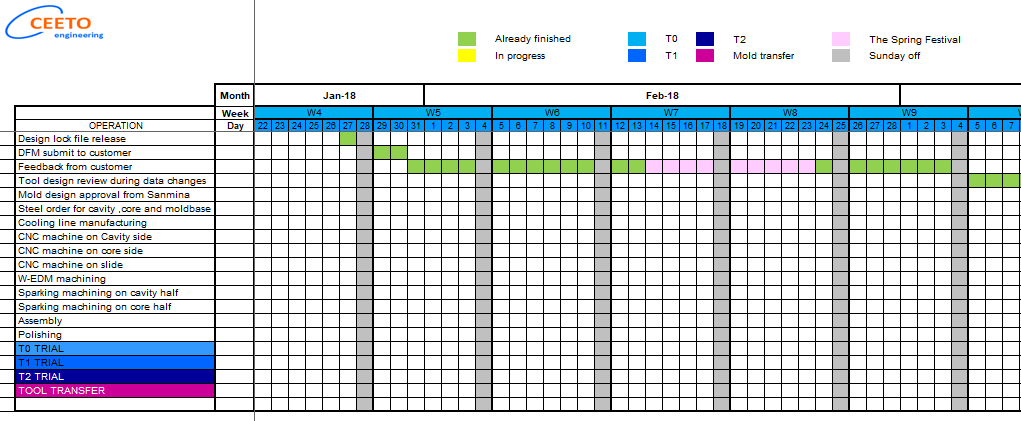

When we receive your official purchasing order of plastic fan blade injection mould, we will set up an internal meeting with mould designer, Project Manager, Production Manager, Project Manager will be in charge of the whole program since this design stage to mould shipment after mould inspection approval, and report to you mould design progress and machining processing progress with weekly report which means that he or she will report you very week about jobs that we do on this program, here is weekly report showing you dynamic timing chart:

Quality Control For Plastic Fan Blade Injection Mould

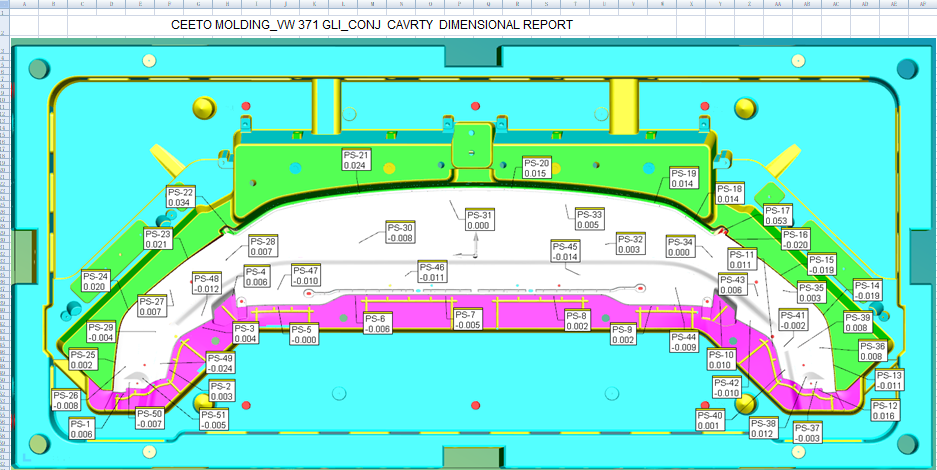

When we receive mould steel blocks, we ask for steel certification and steel inspection by ourselves, when we make the first mould tryout, we measure plastic sample parts using calipers and CMM measuring equipments, we also measure the critical dimensions on plastic fan blade injection moulds and analyze the reasons of all the "NG" points on measuring reports, we will share these reports with you and find solutions together with you to improve moulds. Here is example of measuring report for mould:

We warmly welcome you to send out an inquiry to us, we will give you mould cost in details with our professional working procedures and strict program management, if you have any technical questions, please don't hesitate to keep us informed, looking forward to hearing from you.