Payment Type:L/C,T/T,D/P,D/A,Paypal

Incoterm:FOB,CFR,CIF,FCA,CPT,EXW,FAS,CIP,DEQ,DDP,DES,DAF,Express Delivery,DDU

Min. Order:1 Set/Sets

Transportation:Ocean,Air,Express,Land

Port:Ningbo,Shanghai

$1000-50000 /Set/Sets

Model No.: CT-10101

Brand: Ceeto

Place Of Origin: China

Forming Method: Plastic Injection Mould

Product Material: Plastic

Product: Household Product

Shaping Mode: Injection Mould

Surface Finish Process: Powder Coating

Mould Cavity: Single Cavity

Plastic Material: PE

Runner: Hot Runner

Design Software: UG

Installation: Fixed

Certification: ISO

Standard: HASCO

Mold Steel: NAK80, 718HH, H13, CHINA P20 etc.

Packaging: Wooden box

Productivity: 500000shots/mold life

Transportation: Ocean,Air,Express,Land

Place of Origin: China

Supply Ability: 10sets/month

Certificate: ISO

HS Code: 8480790090

Port: Ningbo,Shanghai

Payment Type: L/C,T/T,D/P,D/A,Paypal

Incoterm: FOB,CFR,CIF,FCA,CPT,EXW,FAS,CIP,DEQ,DDP,DES,DAF,Express Delivery,DDU

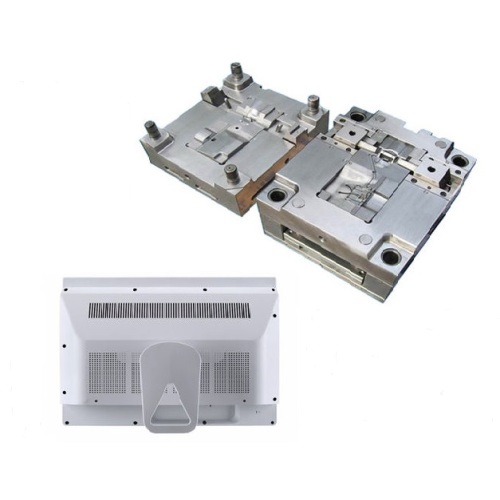

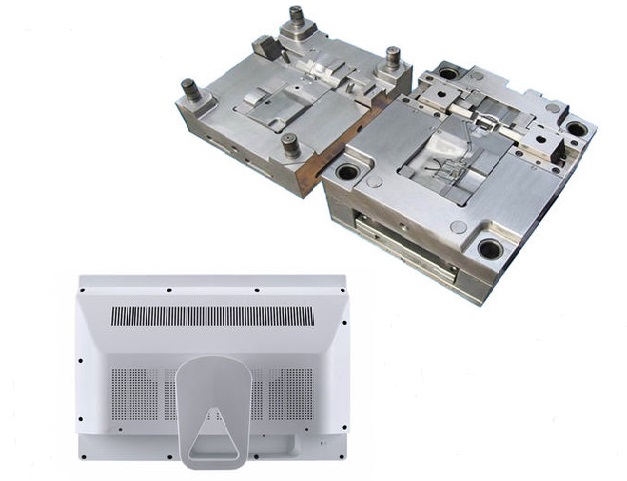

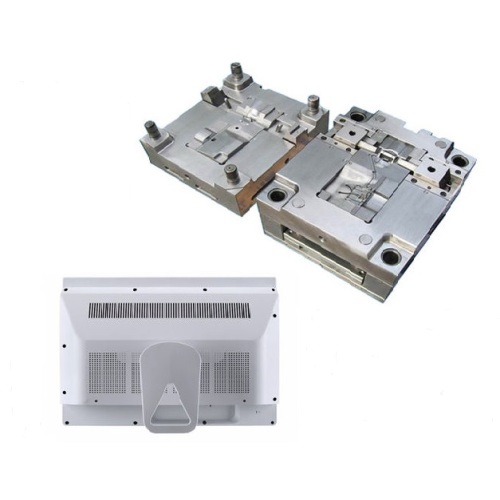

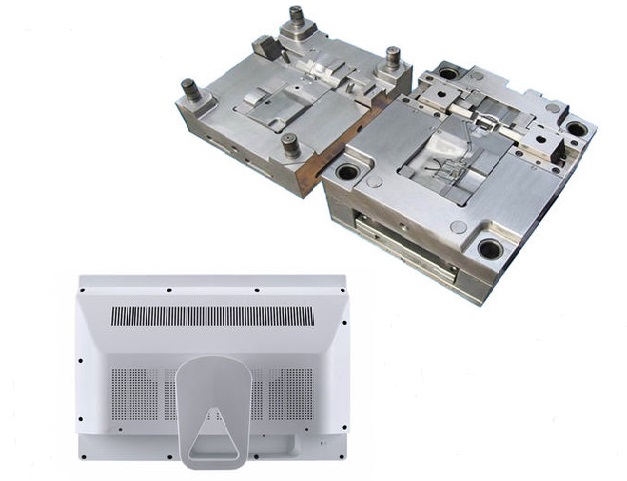

The housing of the television has a front frame and a back cover, The quality of the outer surface is required no flash, marks of ejection and any scratching. At the same time, this is main structure of television and display devices, it requests strong not weak on the Television Housing Injection Mould, welding line posotion must be considered during mould design.

Considering Television and Display Housing and Back Cover is not transparent, Usually, the greater the crystallinity, the greater the density of plastics and the greater the rigidity, and corrosion resistance must be considered, ABS plastic resin is the first option for molding material. Ceeo company has a group of engineering members who are professional to analyse product structure and mould design, they are skilled with good knowledge of molding. It's very important to design the moud at the beginning. For example, parting surface and parting line definition. We must consider them as follows:

Gate position design for Television Front Frame and Back Cover ( Display Housing ) Plastic Mould

In the design of this injection mould, the position and size of the gate are strict, so it may be necessary to modify the size of the gate after the initial mold test. we normally consider the following:

Due to the relatively large volume of the plastic parts, the relatively high temperature of the part of the die kernel, and the lower temperature caused by the external contact with air, the temperature is prone to produce uneven temperature distribution, and the characteristics of the mould materials such as thermal expansion, cold expansion and contraction. So that the mold will produce varying degrees of deformation, so cooling line design is very critical.

Television/Computer/Display Front Frame and Back Cover Shell Housing Injection Mould Technical Specification

If you have any technical questions about Television/Computer/Display front frame and back cover products and moulds, please don't hesitate to contact us at any time, we shall be very glad to give you response in 24 hours, warmly welcome you to visit our factory, and we do wish you to receive your RFQ in a quick time, looking forward to hearing from you, thank you very much.