Payment Type:L/C,T/T,D/P,D/A,Paypal

Incoterm:FOB,CFR,CIF,FCA,EXW,FAS,CPT,CIP,DEQ,DDP,DDU,Express Delivery,DES,DAF

Min. Order:1 Set/Sets

Transportation:Ocean,Air,Land,Express

Port:Ningbo,Shanghai,Shenzhen

$20000≥1Set/Sets

Model No.: CT-10877

Brand: Ceeto

Place Of Origin: China

Forming Method: Plastic Injection Mould

Shaping Mode: Injection Mould

Surface Finish Process: Polishing

Mould Cavity: Single Cavity

Plastic Material: ABS

Process Combination Type: Single-Process Mode

Application: Household Appliances

Runner: Hot Runner

Design Software: UG

Installation: Fixed

Certification: ISO

Standard: HASCO

Customized: Customized

Product Material: Plastic

Product: Household Product

Packaging: Wooden box

Productivity: 500000shots/mold life

Transportation: Ocean,Air,Land,Express

Place of Origin: China

Supply Ability: 5sets/month

Certificate: ISO

HS Code: 8480790090

Port: Ningbo,Shanghai,Shenzhen

Payment Type: L/C,T/T,D/P,D/A,Paypal

Incoterm: FOB,CFR,CIF,FCA,EXW,FAS,CPT,CIP,DEQ,DDP,DDU,Express Delivery,DES,DAF

Ceeto Mold has rich experience to design high quality plastic injection molds, our company service scope refers to Plastic Injection Mould, Injection Molding Automotive Parts including Automotive Interior Plastic Injection Mould and Automotive Exterior Plastic Injection Mould. As well as Home Appliance Injection Mould, Daily Commodity Injection Mould etc.

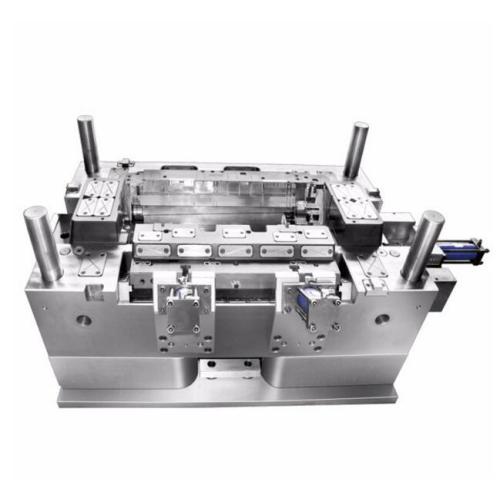

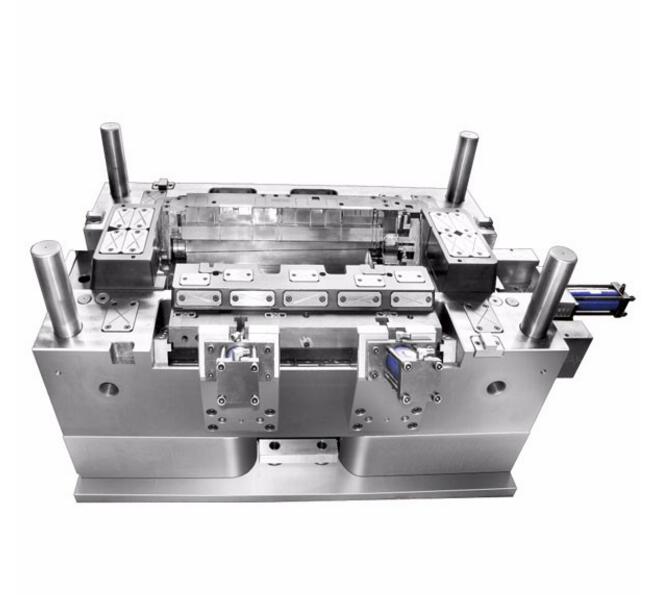

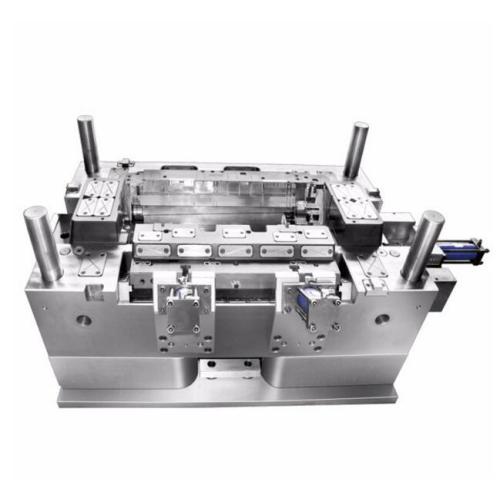

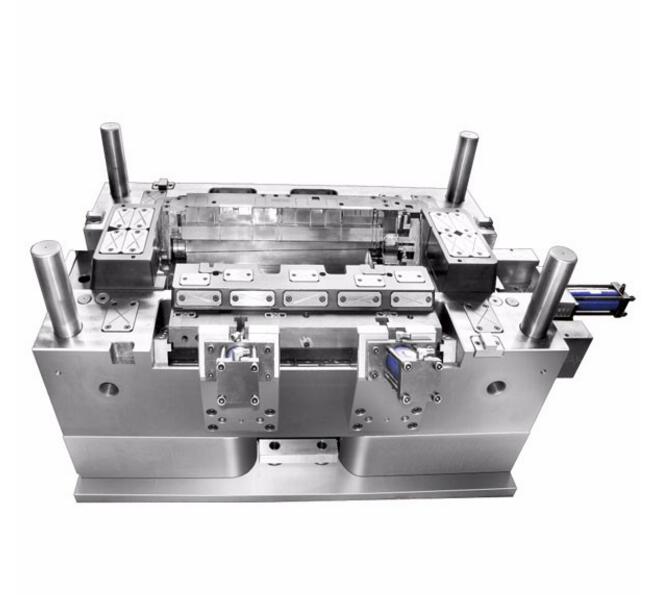

Split Air Conditioning plastics Shell injection Mould, Ceeto Molding has been making a lot of plastic injection moulds for home air conditioner and commercial air conditioner fields, accumulated rich experience in design and processing of air conditioner plastic moulds, customers are very satisfied with all the performances that we have been made.

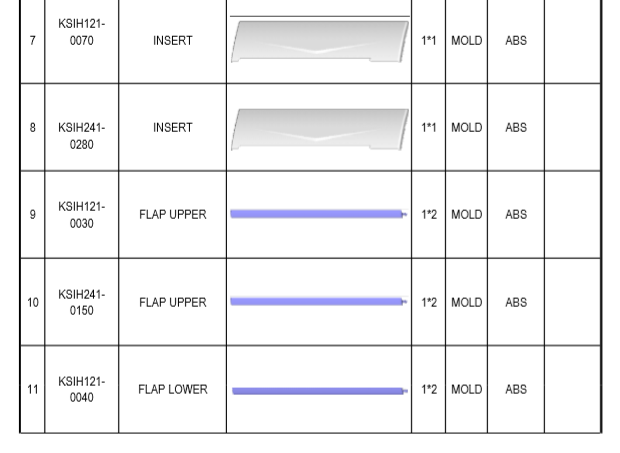

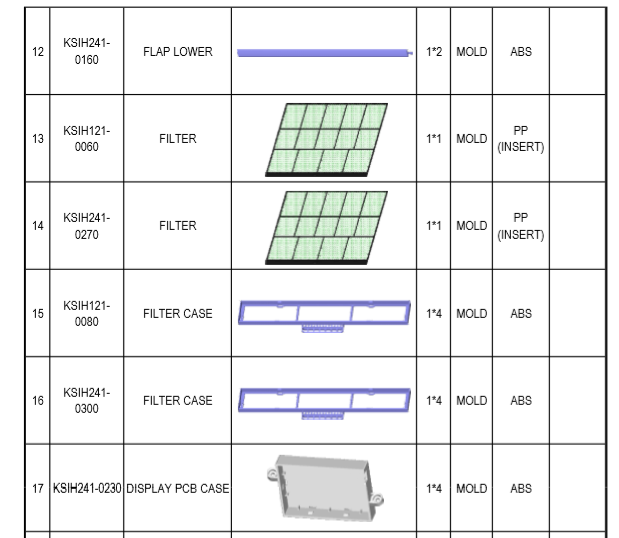

Outdoor air conditioner plastic part list

Detailed Mould Description for Frame

Quality Control about Split Air Conditioning plastics Shell injection Mould

For the Q/C of mould, there are 3 steps:

1. Mould Material Q/C

- Mould Steel Checking ( Hardness, flaw detection, surface defects )

- Mould Standard Spare Parts Checking( hardness, size, flaw checking )

2. Mould Making Process Q/C

- design checking (part design, mould design, mould engineering drawing)

- checking each part of mould's size after machining, according to 2D drawing

- mould testing(check mould running condition)

3. Check with customer's requirement again before mould shipping.