Payment Type:L/C,T/T,D/P,D/A,Paypal

Incoterm:FOB,DAF,DES,CFR,CIF,EXW,FAS,FCA,CPT,CIP,DEQ,DDP,DDU,Express Delivery

Min. Order:1 Piece/Pieces

Transportation:Ocean,Land,Air,Express

Port:Ningbo,Shanghai,Shenzhen

$1000-10000 /Piece/Pieces

Model No.: CT2023-1009-01

Brand: Ceeto

Place Of Origin: China

Forming Method: Plastic Injection Mould

Mold Cavity: 1 cavity mold

Mold Steel: NAK80, 2738, P20 etc as per different volume

Mold Dimensions: Can be designed as per your injection machine

Hot Runner System: Moldmaster, Synventive, Yudo and so on as per your requirements

Cycle Time: 45s~ 55s

Injection Molding Machines: 320T ~ 550T

Plastic Resin: Can be ABS, PP, PC+ABS and so on.

Moldlife: We support moldlife from low volume mold or prototype type to mass production tools ( 100000shots to 1000000shots)

Hydraulic Cyliner: Yes, supported.

Mold Spare Parts: We can prodive you with one set of easy damage mold components during our warranty

Product Material: Plastic

Product: Household Product

Packaging: Plywood wooden boxes

Productivity: 50PCS MOLD/MONTH

Transportation: Ocean,Land,Air,Express

Place of Origin: China

Supply Ability: 50pcs of molds/month

Certificate: IS09001:2015

HS Code: 8480790090

Port: Ningbo,Shanghai,Shenzhen

Payment Type: L/C,T/T,D/P,D/A,Paypal

Incoterm: FOB,DAF,DES,CFR,CIF,EXW,FAS,FCA,CPT,CIP,DEQ,DDP,DDU,Express Delivery

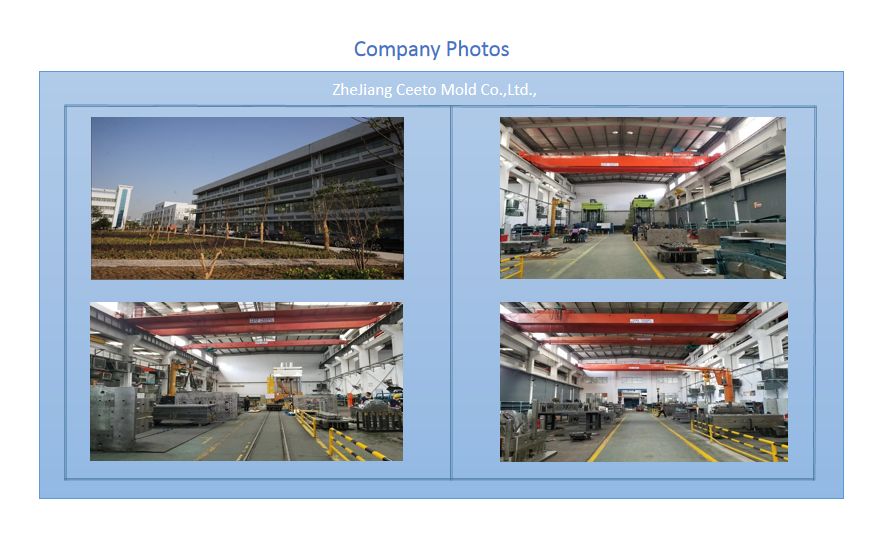

We support customization on plastic injection molds on Plastic Hand Dryer, mainly for outer hand dryer housing parts, side parts and other platsic components, our service scope from plastic 3D printing, prototype injection mold design and manufacturing to production injection mold design and manufacturing.

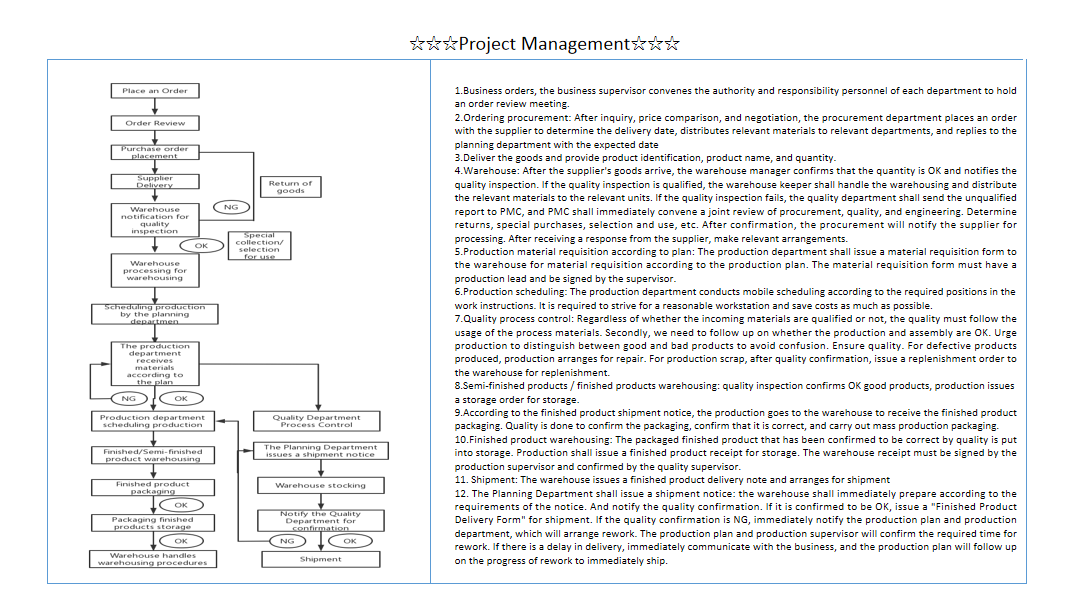

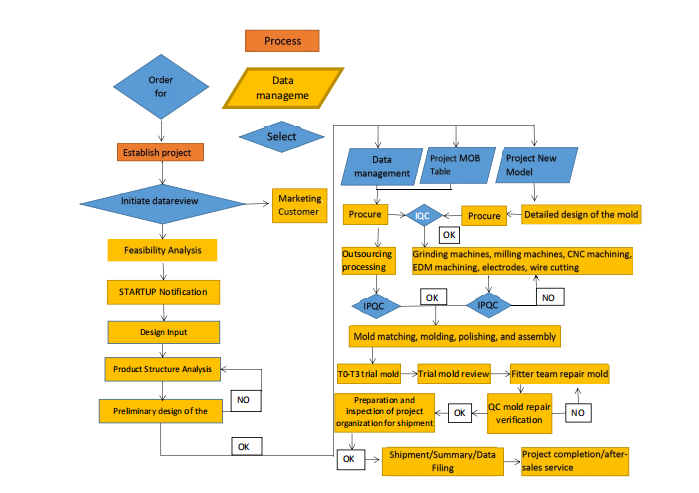

Zhejiang Ceeto Mold company has very strict Plastic Injection Mold building processes, injection mold first of all to carry out the mold design, mold designers according to the shape of the product, size and injection process requirements, the top of the mold structure and parts of the size, the design is approved by the customer, before the mold processing.

Mold processing includes milling machine processing, wire cutting, electric discharge, polishing and other processes. The first is the machining process of the lathe and the milling machine, and the basic parts of the mold are milling to achieve the size of the design requirements.

Then, wire cutting is carried out to cut the outline of the mold. The next step is EDM, which processes small parts of the mold by means of discharge corrosion, and finally polishes to make the surface of the mold smooth and smooth.

After plastic mold processing is completed,, various components are assembled according to mold design requirements, and then the mold is going to be fully tested. The mold test mainly includes the opening and closing action of the mold, the adjustment of the ejector mechanism, inspection of the cooling system, inspection of the hot runner system of the hot runner mold, and so on

…… FAQ ……

Q1: Do you send samples for customized products?

A: Yes, we,Zhejiang Ceeto Mold Co., Ltd. is mainly manufacturing customized stainless steel products. We welcome sample orders to test and check product quality.Mixed samples are also acceptable for us.

Q2: What about deep drawing dies development delivery time?

A: lt usually takes 25 days ~ 45 days stamping dies such as deep drawing dies according to different products, much more complicated products will take longer time for example approx.. 45 days.

Q3: Do you have a minimum order quantity limit?

A: The minimum order quantity is low, and 1pc sample is available for quality inspection

Q4: How do you deliver sample goods and how long does it take to arrive?

A: We usually deliver sample goods by DHL.UPS.FedEx or TNT. It usually takes 3-5 days to arrive Aviation and shipping are also optional.

Q5: How to purchase stainless steel products?

A: First. kindly share with us your technical request or application requirements such as sample or 2D drawings or 3D models. Secondly, we offer you a reasonable quotation in details according to your request. Customers confirm samples and place deposit for formal order.Then, we arrange production or stamping dies development.

Q6: Can my logo be printed on stainless steel products?

A: Yes. Please inform us before our production and confirm any logo design according to our samples.