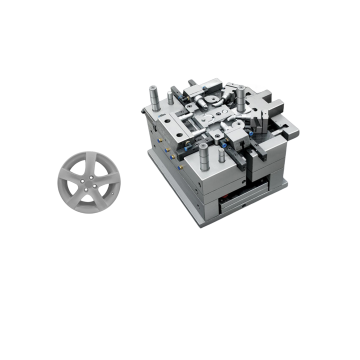

Plastic car exterior parts refer to front and rear bumper moulds, fog lamp moulds, and grilles and all plastic accessories, are requesting high quality with hardened

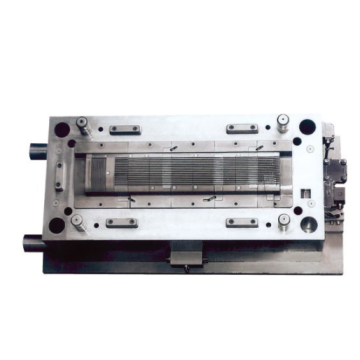

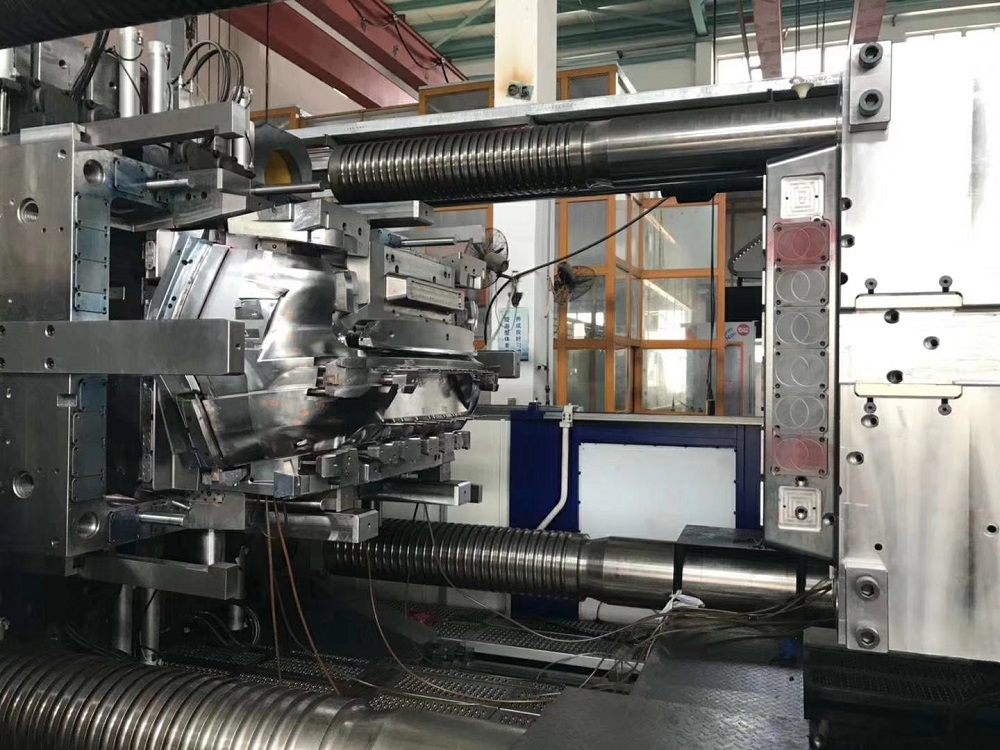

Normally, you and we attend the validation procedure together and sign off after checking. What we are checking usually are as follows:

- Compatibility with Injection Machine to be used

- Is size of the mould ( Leight* width* Height ) correct?

- Is weight of the mould is correct?

- Are lifting eyebolts fully seated on the mold and not interfering with mold action?

- Are all transportation bars installed and in correct color as you request?

- Are knock-out holes for mechanical ejection and the layout correct as designed?

- Is electric box wired correctly as per injection machine standard?

- Are dimensions of locating ring correct?

- Is radius and orifice diameter of sprue bush correct?

- Are clamping features correct?

- Is the mold construction compatible with robot gripping if applicable to take off part?

Plastic car bumper mould material and heat treatment

What we will also inspect mould material and heart treatment as follows:

- Is any welding used on mold? Is welding process correct for the steel used?

- Have all mold plates been stamped with markings?

- Provide the heat treatment certificate and hardness for all applicable mold components

- Are moving parts nitrided? Provide nitride certificate.