Payment Type:L/C,T/T

Incoterm:FOB,CFR,CIF,FCA

Min. Order:40 Set/Sets

Transportation:Ocean,Air

Port:Ningbo,Shanghai

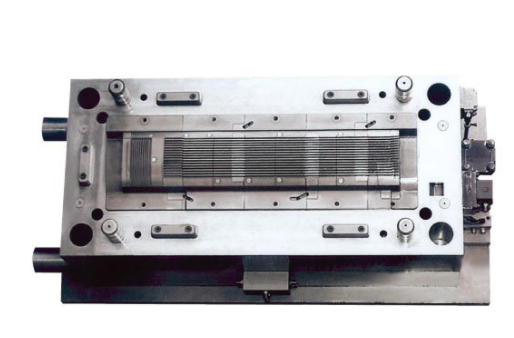

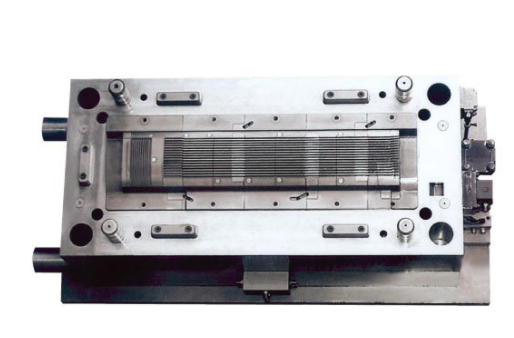

Model No.: CT-10554

Brand: Ceeto

Shaping Mode: Injection Mould

Surface Finish Process: Polishing

Mould Cavity: Multi Cavity

Plastic Material: ABS

Process Combination Type: Single-Process Mode

Application: Car

Runner: Hot Runner

Design Software: UG

Installation: Fixed

Certification: ISO

Standard: HASCO

Customized: Customized

Packaging: Wooden box

Productivity: 500000shots/mold life

Transportation: Ocean,Air

Place of Origin: China

Supply Ability: 30pcs/month

Certificate: ISO

HS Code: 8480790090

Port: Ningbo,Shanghai

Payment Type: L/C,T/T

Incoterm: FOB,CFR,CIF,FCA

Auto air conditioning system is a device for refrigeration, heating, air exchange and air purification. It can provide a comfortable environment for passengers, reduce the fatigue strength of drivers, and improve driving safety. Ceeto Molding is professional mold maker for making Automotive air conditioner plastic injection moulds for more than 20 years, we export about 400 sets moulds yearly to most countries such as USA, Mexico, Australia, Canada, Egypt, Malaysia etc. We have been made all kinds of car air conditioner plastic moulds for most of OEMs.

Detailed Mould Information

FAQ:

Q1: What tolerances can you achieve for Automotive air conditioner Plastic Injection Mould?

There is not a given set of tolerances that fits all processes and materials. In every case, the final tolerances on your part will depend on a number of factors, including but not limited to:

We will review your design and provide a design for manufacturing review, pointing out any areas where we may not be able to achieve your desired tolerances. It`s helpful to us if you can specify which areas in your design have critical tolerances that must be met and which can be slightly modified if needed to reduce time and costs involved.

Q2: How do you ensure your Automotive air conditioner mould quality?

In order to deliver high-quality parts every time, we`ve instituted the following steps to ensure you get parts that meet and exceed your expectations.

Q3: Is the lead time in working days or calendar days?

Lead times are quoted in working days. As per our terms and conditions, quoted lead times commence only after completion and confirmation of design for manufacturing review and the beginning of actual production.

Q4: How long does a quotation take?

In most cases, we respond within a couple of days of receiving an RFQ. However, there may be situations when we must source material from an external supply and therefore the quotation may be delayed accordingly.

Q5: What is the difference between a multi-cavity mold and a family mold?

A multi-cavity mold has multiple cavities of the same part; a family mold produces a set. For instance, for an electronic enclosure, you may need a front, back, battery door, and a button. Those could all be molded at once in a family mold.

Q6: How long does it take to build an Automotive air conditioner injection mold?

Depending on complexity and our tool room load, it can range from 2 to 12 weeks.

Q7: Can I modify the mold after the first run?

We can modify our steel molds by additional machining, fill-in welding, welding in additional material, or inserting a replacement feature, for a reasonable cost. If the changes are too great, however, producing a new mold may be more cost-effective than reworking the existing one.