Privacy statement: Your privacy is very important to Us. Our company promises not to disclose your personal information to any external company with out your explicit permission.

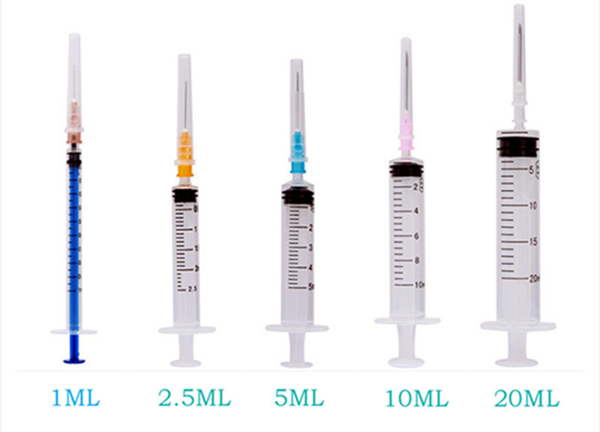

Syringe is a common medical device, its common structure generally includes injection push and pull parts, syringes, needles, etc., this kind of syringe is simple to make, easy to use, syringe barrel is made of plastic, and usually there are scale instructions indicating the volume of liquid in the syringe, generally use 2 ml, 5 ml, 10 ml or 20 ml syringe, occasionally use 50 ml or 100 ml, intradermal injection with 1 ml syringe.

Medical disposable syringe is made of polymer polypropylene material, divided into three-piece and two-piece, three-piece structure for core rod, rubber stopper, jacket three pieces and injection needle, outer packaging, two-piece structure is core rod, jacket and injection needle, outer packaging composition. One of the challenges in the production of medical disposable syringes may be the assembly between the stainless steel needle tube and the plastic needle plug. This joint is essential for the safety of the syringe.

Disposable Medical Sterile Syringe, GB15810-2019, Body Fit (Positive Pressure Seal, Negative Pressure Seal), Slip, Luer Joint Test.

Disposable medical sterile syringe, GB15811-2016, needle puncture artificial skin, needle to needle connection force, needle to sheath extraction force, needle flow test.

Disposable medical low resistance syringe YY/T-2013 (positive pressure seal, negative pressure seal), sliding property, Luer joint test.

Stainless steel needle tube for manufacturing medical devices GB/T18457-2015, rigidity and toughness test

Disposable syringes are one of the commonly used medical devices in the medical field, and their production requires a series of technological processes.

The main raw materials for disposable syringes are polypropylene (PP) and high-density polyethylene (HDPE). Before production, these raw materials need to be tested to ensure that they meet the requirements. It is then mixed according to the ratio requirements to make a uniformly colored drug tube and piston.

After the drug tube is made, it needs to be stretched and then thermoformed to make it a disposable syringe body. The production of pistons requires injection molding of polypropylene, and processing such as polishing and deburring.

Disposable syringe assembly requires the piston to be inserted into the drug tube to ensure verticality and sealing. At the same time, the identification information needs to be printed on the syringe.

The assembled syringe needs to be packaged, and the common packaging method is carton or splint packaging. The syringe needs to be inspected before packaging to ensure that it is qualified.

Some problems in the production process of syringes, such as complex production process, requiring a lot of manual operation, and very high requirements for raw materials, so a high degree of fine management is required. In addition, it is necessary to avoid the use of expired or non-compliant raw materials in production, improve the standards of quality control and packaging labeling, and prevent the appearance of non-conforming products.

In short, the production process of disposable syringes is very important and affects the treatment effect in the medical field. Production enterprises need to strengthen production management to ensure product quality and safety.

Ceeto Mold is engaged in injection mold production manufacturers, in strict accordance with injection production standards, manufacturing sterile medical syringes, we use high-quality raw materials, through exquisite technology to manufacture syringes that meet international standards. We provide high-quality customized services and after-sales services to meet the needs of customers.

New plastic products or plastic sample parts are normally produced by plastic injection molds. Injection molds are usually made of a specified steel metal with good thermal conductivity. In addition...

Sometimes we are facing some technical problems in the molding of plastic injection molds , such as sticky issues on mold cavity, parting surface burrs, weld lines, sink marks, ejector marks and so...

Ceeto Mold has rich experience to design high quality plastic injection molds, here we summarize 6 key points how to design well about plastic injection molds. Key point 1: Firstly we have to define...

PC plastic resin is polycarbonate which is widely used in plastic injection molding industry and because of its excellent mechanical properties, plastic injection molding business is one of our main...

Email to this supplier

Privacy statement: Your privacy is very important to Us. Our company promises not to disclose your personal information to any external company with out your explicit permission.

Fill in more information so that we can get in touch with you faster

Privacy statement: Your privacy is very important to Us. Our company promises not to disclose your personal information to any external company with out your explicit permission.