Payment Type:L/C,T/T,D/P,D/A,Paypal

Incoterm:FOB,CFR,CIF,FCA,EXW,FAS,CPT,CIP,DEQ,DDP,DES,DAF,Express Delivery,DDU

Min. Order:1000 Set/Sets

Transportation:Ocean,Air,Land,Express

Port:Ningbo,Shanghai

$10000≥1000Set/Sets

Model No.: CT-10876

Brand: Ceeto

Place Of Origin: China

Forming Method: Plastic Injection Mould

Product Material: Plastic

Product: Household Product

Shaping Mode: Injection Mould

Surface Finish Process: Polishing

Mould Cavity: Single Cavity

Plastic Material: SAN

Process Combination Type: Single-Process Mode

Application: Household Appliances

Runner: Hot Runner

Design Software: UG

Installation: Fixed

Certification: ISO

Standard: DME

Customized: Customized

Packaging: Wooden box

Productivity: 500000shots/mold life

Transportation: Ocean,Air,Land,Express

Place of Origin: China

Supply Ability: 30sets/month

Certificate: ISO

HS Code: 8480790090

Port: Ningbo,Shanghai

Payment Type: L/C,T/T,D/P,D/A,Paypal

Incoterm: FOB,CFR,CIF,FCA,EXW,FAS,CPT,CIP,DEQ,DDP,DES,DAF,Express Delivery,DDU

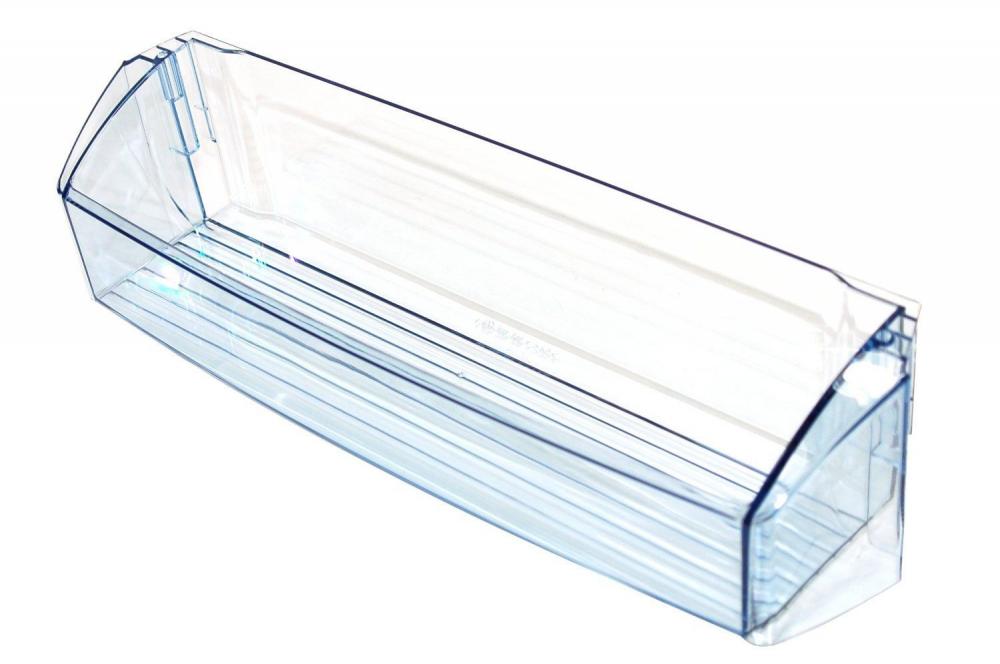

Fridge Plastic Cover Bottle Shelf Plastic Product or Refrigerator Plastic Door Shelf Bin Moulds are injected by PC/ABS, PC&SAN, or ABS plastic resins. Fridge Plastic Bottle Shelf Injection Mould design is requested very good cooling line system, high polishing on visible parting surface must be applied.

Fridge Door Shelf Bin Plastic Injection Mould Specifications

Hot runner YUDO brand name is recommended.

All moulds must be designed for automatic operation on request.

Machining Equipment

Our service

In-time supply the quotation with reasonable price to Fridge door bin shelf plastic mould

In-time supply part design and mould design

In-time response by e-mail with weekly report during the whole process such as CNC machining, EDM and mold assembly etc.

In-time mould test and sample delivery

On time delivery

Good After-sale service

Quality Control about Fridge Plastic Bottle Shelf Mould

For the Q/C of mould, there are 3 steps:

1. Mould Material Q/C

- Mould Steel Checking ( Hardness, flaw detection, surface defects )

- Mould Standard Spare Parts Checking( hardness, size, flaw checking )

2. Mould Making Process Q/C

- design checking (part design, mould design, mould engineering drawing)

- checking each part of mould's size after machining, according to 2D drawing

- mould testing(check mould running condition)

3. Check with customer's requirement again before mould shipping.