Payment Type:L/C,T/T,D/P,D/A,Paypal

Incoterm:FOB,CFR,CIF,FCA,EXW,FAS,CPT,CIP,DEQ,DDP,DES,DAF,Express Delivery,DDU

Min. Order:1000 Set/Sets

Transportation:Ocean,Air,Land,Express

Port:Ningbo,Shanghai

$10000≥1000Set/Sets

Model No.: CT-10515

Brand: Ceeto

Place Of Origin: China

Forming Method: Plastic Injection Mould

Product Material: Plastic

Product: Household Product

Shaping Mode: Injection Mould

Surface Finish Process: Polishing

Mould Cavity: Multi Cavity

Plastic Material: PC

Process Combination Type: Single-Process Mode

Application: Home Use

Runner: Hot Runner

Design Software: Pro-E

Installation: Fixed

Certification: ISO

Standard: DME

Customized: Customized

Packaging: Wooden box

Productivity: 500000shots/mold life

Transportation: Ocean,Air,Land,Express

Place of Origin: China

Supply Ability: 15 sets/month

Certificate: ISO

HS Code: 8480790090

Port: Ningbo,Shanghai

Payment Type: L/C,T/T,D/P,D/A,Paypal

Incoterm: FOB,CFR,CIF,FCA,EXW,FAS,CPT,CIP,DEQ,DDP,DES,DAF,Express Delivery,DDU

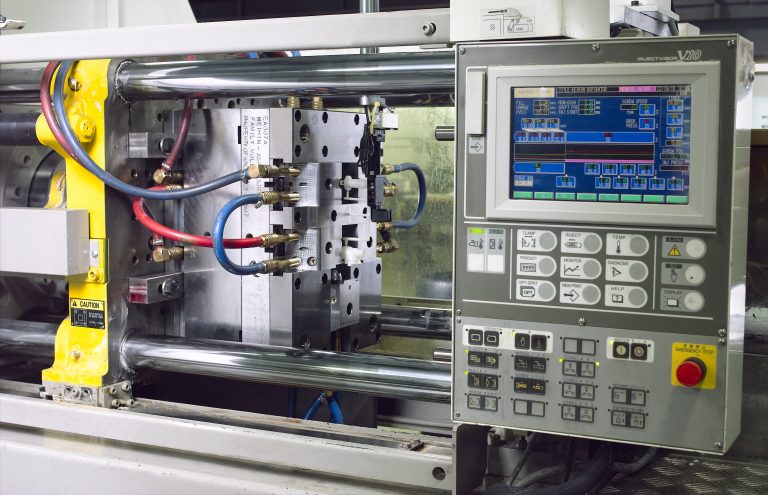

Road lighting and street lamp products are producted by Road lighting Plastic Injection Mould, injection material can be PMMA, PBT+30%GF, PC, Road lighting plastic mould can be made by 2-cavity, 4-cavity, and 8-cavity depends on mould life and production line volume. Mold cavity and core steel can be NAK80 high quality steel due to high wattage requirement. Mold life can be 500000shots to 1000000shots.

LED light or lamp plastic injection mould are widely applied in Road lighting system and Household lighting system as well, Ceeto molding has rich experience in making LED lighting plastic moulds for many years, according to customer's requirement about LED light plastic mould life, from 300000shots to 1000000shots, mould steel must be choosen correctly and properly, and high polishing processing must be applied as per cusotmer's requirements.

LED lighting plastic injection mould description:

| Mould cavity and core steel | NAK80,S136,P20HH,1.2738,718H Harded steel etc. |

| Runner | Hot runner ( Yudo, Synventive, HRS, Mold-master etc.) or cold runner |

| Type of gate | Pin point gate or sub-gate, edge gate etc. |

| Plastic injection material | PMMA, PC, PBT+30%GF, etc. |

| Mould cavity | Single cavity, or multi-cavity ( 2 cavity, 4 cavity, 8 cavity etc.) |

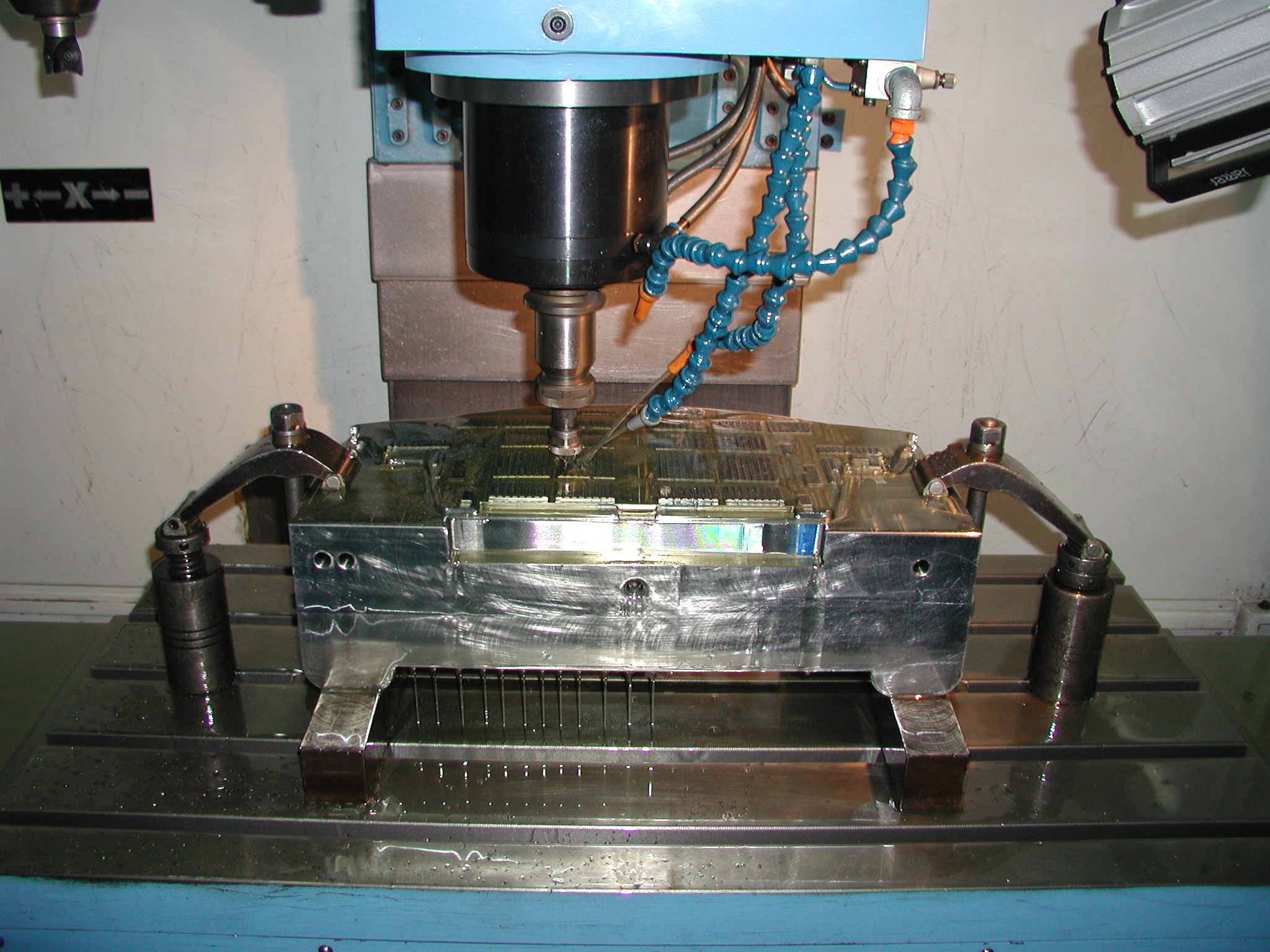

| Machining process for mould | CNC high speed milling, W-EDM cutting, Water line drilling, and basic lather and grinding machining etc. |

| Surface treatment for mould | High polishing |

| Leadtime | 30 days to 50 days depending on product structure |

| Shipping Incoterms | FOB (Shanghai, Ningbo), CIF, DDU etc. |

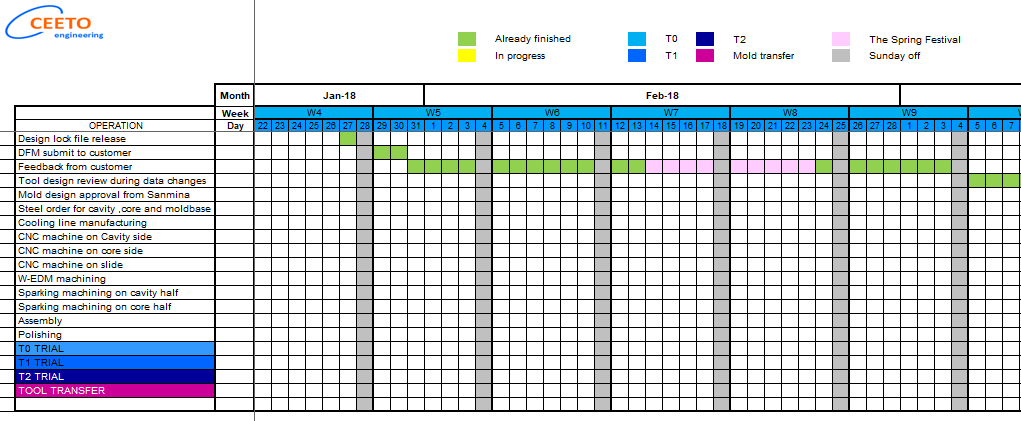

When LED lighting plastic injection mould purchasing order is placed, we will set up an internal meeting with mould designer, Program Manager, Production Manager and all the teams will be involved in this program in order to prepare for design and manufacturing, mould designer will be responsible for making DFM, mould design and optimization, moldflow analyses, including all design details communicating with customers, Program manager will be in charge of the whole program from the mould design stage to mould successfully are approved to be shipped out, he or she will be responsible for following up program schedule and provide customers with timing chart weekly.

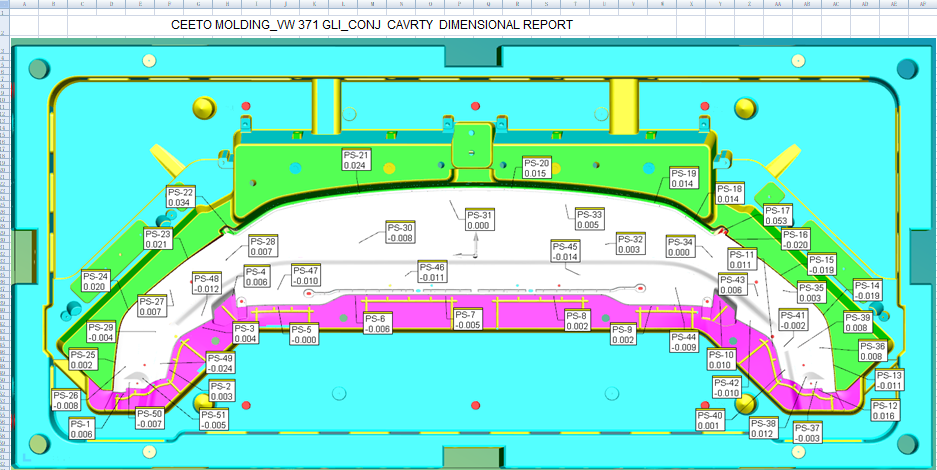

Quality Control to LED lighting plastic mould and plastic sample part, there are several steps internally to control quality and provide customers with high quality injection moulds.

Why choose Ceeto Molding