Model No.: CT-241105-01

Brand: CEETO

Place Of Origin: China

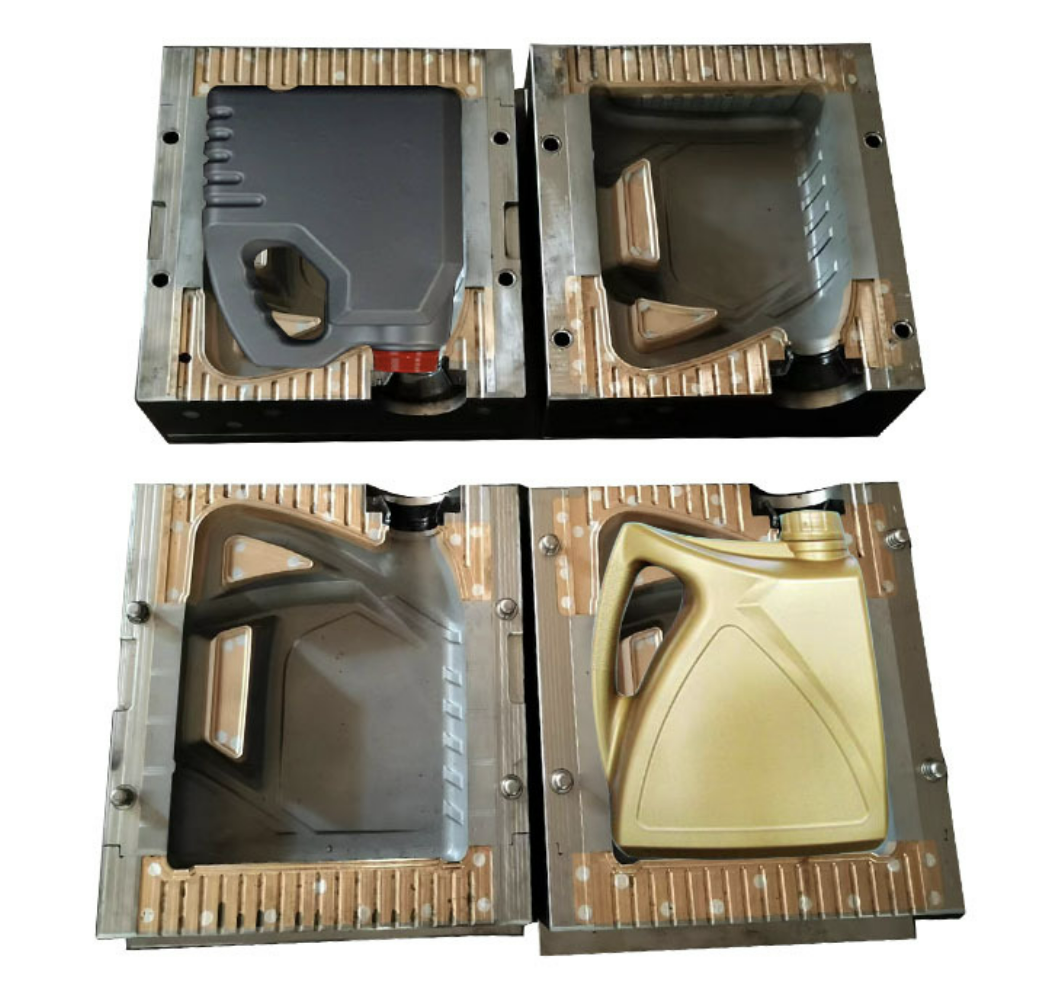

Forming Method: Blowing Mould

Product Material: Plastic

2D Drawing And 3D Modls Available: Platsic resin can be PP,ABS,PET,TPE,PC,PC/ABS,PE,PCR-PP,PCR-PC etc.

Platsic Resin Can Be PP,ABS,PET,TPE,PC: Mold steel can be 718,718H,P20,P20HH,2738,and soon

Mold Base:LKM: Standard components can be Punch,DME,HASCO.

Type Of Gate:cold Runner: Hot runner system can be synventive,Yudo etc.

Ejection System:Ejection Pins: Cooling lines:as per client's requirements.

Moldflow Analysis:included: 3D printing included if necessary

Support Prototype Molds: Support prototype Molds

Production Mold Life:1500000 Shots: clamping force:as per mold design.

Wall Thickness As Per Product Design: Mold testing:3 official times

Cycle Times:25s: Mold packing:wooden box

Packaging: Carton + pallet+Plastic packing

Productivity: 50+ molds/years

Transportation: Ocean,Land,Air,Express

Place of Origin: Zhejiang,China

Supply Ability: 10000 pcs

Certificate: ISO9001

Port: N,i,n

Payment Type: L/C,T/T,D/P,D/A

Incoterm: FOB,DDP,CFR,DDU,CIF,EXW,FAS,DAF,FCA,DES,CPT,CIP,DEQ

Automotive oil can blow mold: from design to application.

Application: Blow moulds for automotive oil cans are mainly used for the production of containers for the storage and distribution of automotive oil.

Design: The design and manufacture of this type of mold needs to take into account the functionality and durability of the product, as well as the efficiency and cost control in the production process. The following are some key points about the automotive oil can blow mold:

1. Material selection: Blow moulds are usually made of high-hardness steel to ensure durability and accuracy in long-term use. Different steels are suitable for different types of plastics to obtain the best finished product quality and production efficiency.

2. Design considerations: the design needs to consider the functional requirements of the oil pot, such as capacity, shape, opening size, etc. At the same time, it is also necessary to take into account the maintainability of the mold in order to clean and replace worn parts.

3. Production process: Blow molding is a process in which the thermoplastic is heated to a flowing state and then blown into the mold by compressed air to form the desired shape. For the oil pot, this includes the selection of raw materials, heating, pressurization, cooling and other steps.

4. Quality control: strict quality control measures are required in the production process to ensure that each oil can meets the specifications. This includes dimensional checks, appearance checks and functional tests.

5. Environmental factors: Environmental factors also need to be taken into account in the design and production process, such as the selection of raw materials and production processes with less impact on the environment, as well as the possibility of recycling waste oil cans.

The main raw materials for the production of automotive oil cans usually include the following:

1. Plastic: This is the most common material, especially high-density polyethylene (HDPE) and polypropylene (PP). These plastics have good chemical resistance, durability and cost effectiveness. Plastic oil cans are lightweight and easy to form, suitable for mass production.

2. Composite materials: In some advanced applications, composite materials may be used to combine the advantages of a variety of materials to achieve better performance.

If you are looking for quality blow moulds for oil cans, please contact us today. Our oil cans are carefully crafted from the highest quality materials, with excellent corrosion resistance and high strength, environmentally friendly. Make sure you keep your liquids in tip-top condition at all times during storage and transportation. We offer a variety of specifications and designs to meet different needs, and all products undergo rigorous quality testing to ensure superior performance and durability. Whether you are a retailer, wholesaler, car manufacturer.

We can provide you with the most professional solutions and quality after-sales service. Contact us now to experience our high quality products.