Payment Type:L/C,T/T,D/P,D/A,Paypal

Incoterm:FOB,CFR,CIF,FCA,EXW,FAS,CPT,CIP,DEQ,DDP,DES,DAF,Express Delivery,DDU

Min. Order:1 Set/Sets

Transportation:Ocean,Air,Land,Express

Port:Ningbo,Shanghai,Shenzhen

$1000-40000 /Set/Sets

Model No.: CT-10145

Brand: Ceeto

Place Of Origin: China

Forming Method: Plastic Injection Mould

Product Material: Plastic

Product: Household Product

Shaping Mode: Injection Mould

Surface Finish Process: Powder Coating

Mould Cavity: Single Cavity

Plastic Material: PE

Runner: Hot Runner

Design Software: UG

Installation: Fixed

Certification: ISO

Standard: HASCO

Customized: Customized

Packaging: Wooden box

Productivity: 500000shots/mold life

Transportation: Ocean,Air,Land,Express

Place of Origin: China

Supply Ability: 30sets/month

Certificate: ISO

HS Code: 8480790090

Port: Ningbo,Shanghai,Shenzhen

Payment Type: L/C,T/T,D/P,D/A,Paypal

Incoterm: FOB,CFR,CIF,FCA,EXW,FAS,CPT,CIP,DEQ,DDP,DES,DAF,Express Delivery,DDU

How to consider a perfect Plastic Injection Gate Type and Size?Ceeto Mold company to be as a professional Plastic Injection Mold maker and Molding manufacturer, which has more than ten years experience in making plastic molds in such fields as Automotive accessories plastic molds and molding, Home appliance accessories plastic moulds and molding and other Daily commodities plastic molds, Medical device plastic molds etc. To be a good mold maker, we fully know that the gate, also known as the feed gate, is a section of thin short runner (except for the direct gate) connecting the shunt and the mold cavity, which is the key part of the gating system in the plastic mold design.

Its main functions are:

(1) Cavity filled, melt in the gate at the first condensation, prevent its backflow.

(2) Easy to cut in the gate pouring system condensate. The gate sectional area is about 0.03 ~ 0.09 of the shunt sectional area. The length of the gate is about 0.5 mm ~ 2 mm, and the specific size of the gate is generally determined according to experience. The lower limit is taken, and then it is gradually corrected when the mold is tested.

When the plastic melt passes through the gate, the shear rate increases, and the internal friction of the melt intensifies, which increases the temperature of the material flow, reduces the viscosity, improves the flow performance and is conducive to mold filling. But the gate size is too small will increase the pressure loss, condensate speed up, feed difficult, even the formation of jet phenomenon, affecting the quality of plastic parts.

Sprue forms are as follows:

(1) The Direct Gate

Straight gate, also known as the center gate, this gate flow resistance is small, fast feeding speed, in the single cavity mold is often used to form large and deep plastic parts.It is suitable for all kinds of plastics, especially those with high viscosity and poor fluidity, such as PC, PSF, etc.

With straight gate molding shallow and flat when the plastic parts will produce bending and warping phenomenon, at the same time remove gate inconvenience, there are obvious gate traces, sometimes because of the gate location heat concentration, cavity sealing late, internal stress and become the source of cracks, so design, gate should be as small as possible. When forming thin-walled plastic parts, the diameter of the root of the gate is at most 2 times the thickness of the plastic parts.

(2) The Side Gate

Side gate, also known as edge gate, its section is rectangular, generally open on the parting surface, from the plastic part of the side feeding, can be reasonable choice of gate location, especially suitable for more than one cavity. As shown in FIG. 10-12, generally the width B= 1.5mm ~ 5mm, the thickness h= 0.5mm ~ 2mm (or 1/3 ~ 2/3 of the wall thickness of plastic parts), and the length L= 0.7mm ~ 2mm.

(3) The Point Gate

The point gate, also known as the pin gate, is a small size gate, as shown in figure 10-14.Plastic melts have a high shear rate through it. It is widely used in various shell molding parts. The gate can be broken by itself when the mould is opened.

The joint of gate and plastic part, in order to prevent the damage of plastic part when the point gate is broken, can be designed to have the form of small convex boss

The cross section area of the point gate is small, the condensation is fast, and it is not good for feeding.

(4) The Sub-gate

Also known as shear gate, it is evolved from point gate, which is used for three-plate die, while latent gate is used for two-plate die, thus simplifying the structure of the die. The latent gate is arranged on the inside or outside of the plastic part, which does not affect the appearance of the plastic part. In the release of plastic parts when the gate is cut off, but need to have a strong thrust, the strong and tough plastic should not be used.

Direct gate size for normal plastic resins:

| Part weight/g | <35 | < 340 | ≥ 340 | |||

| Main sprue diameter/mm | D | d | D | d | D | d |

| PS | 2.5 | 4 | 3 | 6 | 3 | 8 |

| PE | 2.5 | 4 | 3 | 6 | 3 | 7 |

| ABS | 2.5 | 5 | 3 | 7 | 4 | 8 |

| PC | 3 | 5 | 3 | 8 | 5 | 10 |

Suggested side gate and pin point gate sizes:

| Part thickness | Side gate section dimensions | Point Gate Diameter | Gate length | |

| Depth | Width | |||

| < 0.8 | ~ 0.5 | ~1.0 | 0.8~1.3 | 1 |

| 0.8~2.4 | 0.5~1.5 | 0.8~2.4 | ||

| 2.4~3.2 | 1.5~2.2 | 2.4~3.3 | ||

| 3.2~6.4 | 1.0~3.0 | |||

Our processing for making Plastic Injection Mould

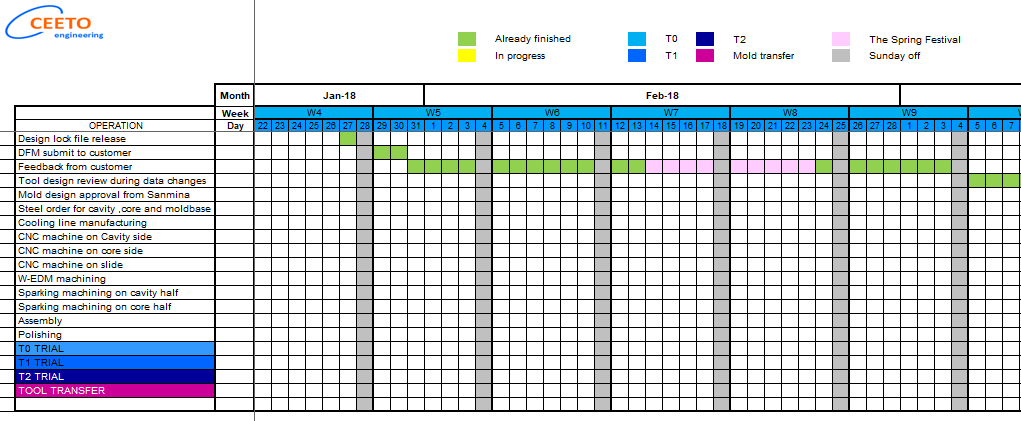

When we receive your official purchasing order, we will set up an internal meeting with mould designer, Project Manager, Production Manager, Project Manager will be in charge of the whole program since this design stage to mould shipment after mould inspection approval, and report to you mould design progress and machining processing progress with weekly report which means that he or she will report you very week about jobs that we do on this program, here is weekly report showing you dynamic timing chart:

Quality Control For Plastic Injection Mould

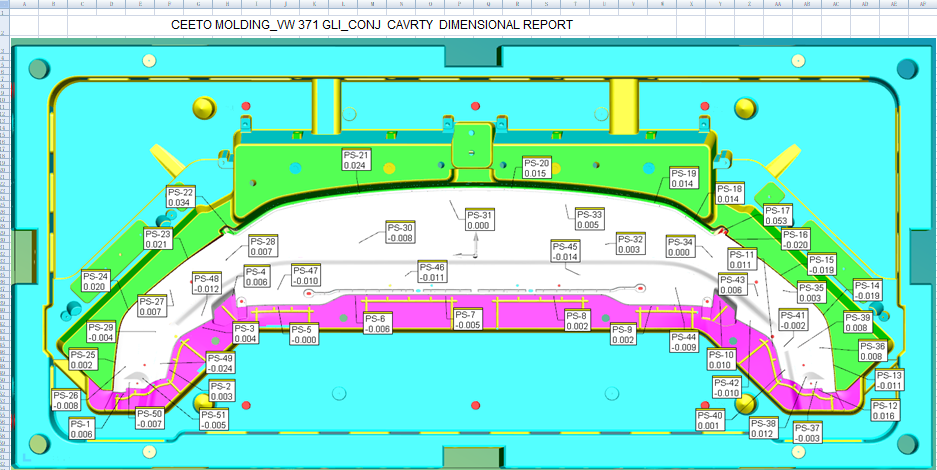

When we receive mould steel blocks, we ask for steel certification and steel inspection by ourselves, when we make the first mould tryout, we measure plastic sample parts using calipers and CMM measuring equipments, we also measure the critical dimensions on plastic fan blade injection moulds and analyze the reasons of all the "NG" points on measuring reports, we will share these reports with you and find solutions together with you to improve moulds. Here is example of measuring report for mould:

Ceeto Mold company warmly welcome you to send out an inquiry to us, we will give you mould cost in details with our professional working procedures and strict program management, if you have any technical questions, please don't hesitate to keep us informed, looking forward to hearing from you, thank you very much.