Payment Type:L/C,T/T,D/P,D/A,Paypal

Incoterm:FOB,CFR,CIF,CPT,EXW,FAS,FCA,CIP,DEQ,DDP,DES,DAF,Express Delivery,DDU

Min. Order:1 Piece/Pieces

Transportation:Ocean,Land,Air,Express

Port:Ningbo,Shanghai,Shenzhen

$1000-40000 /Piece/Pieces

Model No.: CT-10832

Brand: Ceeto

Place Of Origin: China

Forming Method: Plastic Injection Mould

Product Material: Plastic

Product: Household Product

Surface Finishing Process Is Graining Or Texture: Design Software Can Be Pro-E.

Packaging: Wooden box

Productivity: 500000shots/mold life- 1000000

Transportation: Ocean,Land,Air,Express

Place of Origin: China

Supply Ability: 30sets/month

Certificate: ISO

HS Code: 8480790090

Port: Ningbo,Shanghai,Shenzhen

Payment Type: L/C,T/T,D/P,D/A,Paypal

Incoterm: FOB,CFR,CIF,CPT,EXW,FAS,FCA,CIP,DEQ,DDP,DES,DAF,Express Delivery,DDU

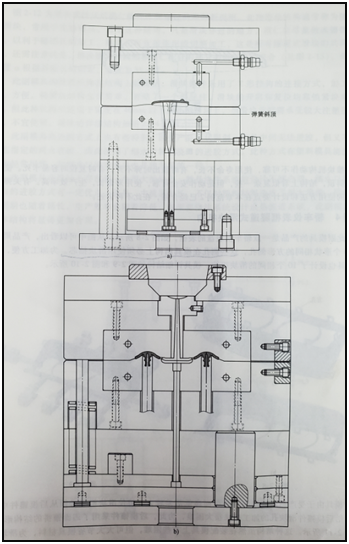

How to make good Battery Cover Plastic Mold? The very important point is to design a good spring angle lifter mechanism on the mold design. This Batter Cover Injetion Mold is a spring angle lifter mechanism working system. With regard to the undercuts of this plastic product, we suggest to use the spring angle lifters because it appears to be complex looking at the Battery Door mold design, but the movement is safe and reliable, the mold service life is more longer, the production efficiency is much more higher. Ceeto company has many years experience in design the Battery Cover Plastic mold. Please see a rough design of spring angle lifter mechanism below.

In fact, spring angle lifter is designed using the principle of spring elastic deformation, so the use of steel is the first key point and the second is the shape of the angle lifter. As long as the two keys are mastered, the design of spring angle lifter is much more simple. The steel used in spring angle lifters must have excellent properties, the most commonly used is special spring steel.

Figure a) is the state that Spring angle lifter has not been assembled into the mold after the angle lifter processing is completed, figure b) is the state that Spring angle lifter has been assembled into the mold after the angle lifter processing is completed, and figure c) is the trend comparison of the elastic deformation before and after the angle lifter assembly. It can be seen that the angle lifter has an angle change before and after assembly.

When the angle lifter is ejected together with the product, the angle lifter is restored to the original state under the action of elastic deformation and the change of angle, thus taking the undercuts of Battery Cover Plastic Product. This angle is not constant, which is determined by the mold designer according to the depth of undercuts design. The minimum deformation space and deformation distance at this angle must be greater than the depth of undercuts.

You also need to design the spring angle lifter with the following main issues:

A) Ejector Pins must be arranged around the angle lifters, because the spring angle lifter can not withstand a greater force.

B) The spring angle lifter is inmovable on the ejector pin plates, it`s unlike the usual angle lifters.

C) The thickness W could not even bigger, normally it`s designed 2-3mm is fine which is determined by the size of angle lifter.

Spring angle lifter is a bit simple processing, easy to use, usually used in the case of very small space, the disadvantage is only suitable for the case of shallow product undercuts, when the undercut is larger than 3mm, it should be cautious use. Because when the undercut is deep, the angle that needs to change is also more larger, the elasticity of angle lifter is easy to fatigue, and the working action is easy to fail.

Material: ABS

Waterproof: IP66

Dimensions (outer): 100 X 68 X 50mm

Material: ABS

Color: White or black

Package includes: 1 X Waterproof Plastic Project Box

FAQ

Q1: Which kind information need for quotation?

A1: 1) Sample photo with size or 2D/3D design

2) Product material

3) The quantity

4) Runner type, cold or hot

5) Mould steel type, P20, 718, 2738, H13, S136, 2316, an so on.

Q2: Product 3D drawing is not available , how should I start the new project?

A2: You can supply us a sample or tell me your idea,we will help to finish part 3D drawing design by scanning.

Q3: How long will be Waterproof Plastic Electronic Project Box mould finished?

A3: Usually it will take more than one month to finish the mold.

Q4: How about Waterproof Plastic Electronic Project Box samples?

A4: After mold finished, We will make some samples for you to check as soon as we finish the mold and then deliver the samples for you to check.