Payment Type:L/C,T/T,D/A,Paypal

Incoterm:FAS,EXW,CFR,FOB,DDU,Express Delivery,DAF,CIF,DES,FCA,CPT,CIP,DEQ,DDP

Min. Order:7 Others

Transportation:Ocean,Land,Air,Express

Port:Ningbo,Shanghai,Shenzhen

$9≥7Others

Brand: Ceeto

Place Of Origin: China

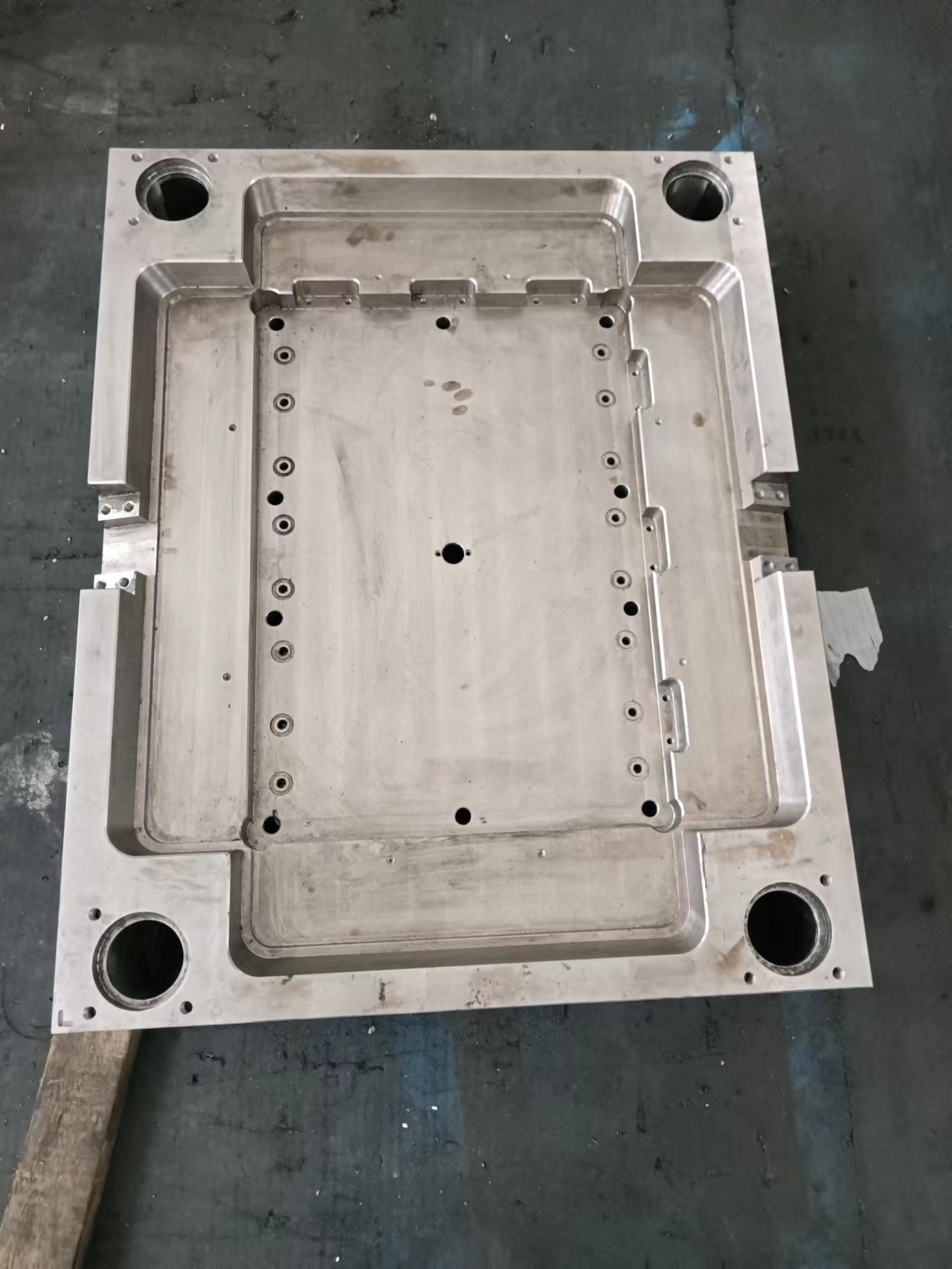

Plastic Molding Process Type: Injection

Processing Service: Moulding

Packaging: carton box with pallets

Productivity: 50molds/month

Transportation: Ocean,Land,Air,Express

Place of Origin: Ningbo,China

Supply Ability: 50molds/month

Certificate: ISO/9001

HS Code: 8480790090

Port: Ningbo,Shanghai,Shenzhen

Payment Type: L/C,T/T,D/A,Paypal

Incoterm: FAS,EXW,CFR,FOB,DDU,Express Delivery,DAF,CIF,DES,FCA,CPT,CIP,DEQ,DDP

Zhejiang Ceeto Mold Co.,Ltd., registed in year 2018, which has a strong plastic injection molds group members and plastic injection processing experts which have rich experience in design and manufacturing plastic injection moulds, die casting molds design and plastic molds manufacturing accordingly. Ceeto company provides customer with high quality injection molds and plastic products injection , die casting products mainly in Automotive field, Home appliance field, Daily consumer products field etc. with reasonable price, fast delivery and high quality. Building area is 11000 square meters. Currently, we have employee 200 and a group of Program Engineers are in charge of projects according to customers from different global regions, 30 technical engineers who are having much experience in designing and developing mold 2D assembly drawings & mold 3D designs.

Injection molding is a common plastic processing process, and its production process includes the following steps:

1. Mold design: Design and make injection molds according to the shape and size requirements of the product. The mold is generally composed of an upper die and a lower die, with an injection cavity in the middle that allows plastic to flow into and form the shape of the desired product.

2. Raw material preparation: Select suitable plastic raw materials, such as polypropylene, polyethylene, polyvinyl chloride, etc., and pre-treatment, such as drying, dyeing, etc.

3. Injection molding: Put the pre-treated plastic particles into the hopper of the injection molding machine, melt and compress the plastic through the rotation of the screw, and then inject the molten plastic into the injection cavity of the mold.

4. Cooling and curing: The plastic in the injection cavity will be cooled by cooling water or air during the injection process, so that it can cure quickly. After curing, the mold is opened and the molded product is removed.

5. Product treatment: The removed product may need to be trimmed, cleaned, assembled and other follow-up treatment to meet the final product requirements.

Injection molding process has the advantages of high production efficiency, stable product quality and short production cycle, and is widely used in automotive parts, electronic product shells, daily necessities and other fields.