Payment Type:L/C,T/T,D/P,D/A,Paypal

Incoterm:FOB,CFR,CIF,FCA,FAS,EXW,CPT,CIP,DEQ,DDP,DES,DAF,Express Delivery,DDU

Min. Order:1 Set/Sets

Transportation:Ocean,Air,Land,Express

Port:Ningbo,Shanghai,Shenzhen

$1000-50000 /Set/Sets

Model No.: CT-10685

Brand: Ceeto

Place Of Origin: China

Forming Method: Plastic Injection Mould

Product Material: Plastic

Product: Household Product

Surface Finishing Process Is Graining Or Texture: Plastic Injection Material Is PP

Packaging: Wooden box

Productivity: 500000shots/mold life

Transportation: Ocean,Air,Land,Express

Place of Origin: China

Supply Ability: 15 sets/month

Certificate: ISO

HS Code: 8480790090

Port: Ningbo,Shanghai,Shenzhen

Payment Type: L/C,T/T,D/P,D/A,Paypal

Incoterm: FOB,CFR,CIF,FCA,FAS,EXW,CPT,CIP,DEQ,DDP,DES,DAF,Express Delivery,DDU

Ceeto company is offering a great line of Plastic Flower Pot Injection Mould that is designed for planting many different kinds of plants for decoration, and for keeping surrounding area green and full with fresh air. These type of planters are commonly demanded in nurseries, homes, offices, restaurants, and hotels to name a few. Having strong base and ideal shape and dimension, it remains stable in rapidly blowing air and heavy rain. The Plastic Garden Planters come in variant of sizes to meet varied planting need of users.

Customized Plastic Flower Pot Mold Description

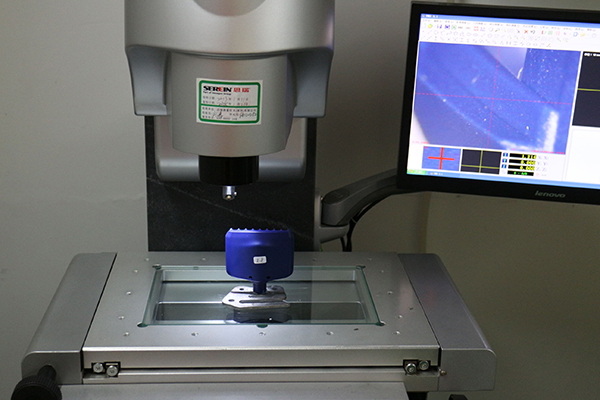

We are able to design and manufacture flow pot injection mould as per your 2D drawing and 3D model of flower pot, we supply you DFM report and moldflow analysis report, we have a strong design engineers team who are capable of providing you the perfect flower pot injection mould perfect design according to shrinkage rate, your injection machine technical data. Mould making refers to rough cutting, fine CNC high speed milling, EDM( Electrical Discharge Machining ), WEDM, water line drilling, mould bed-out via spotting machine and mould assembly fitting by bench works.

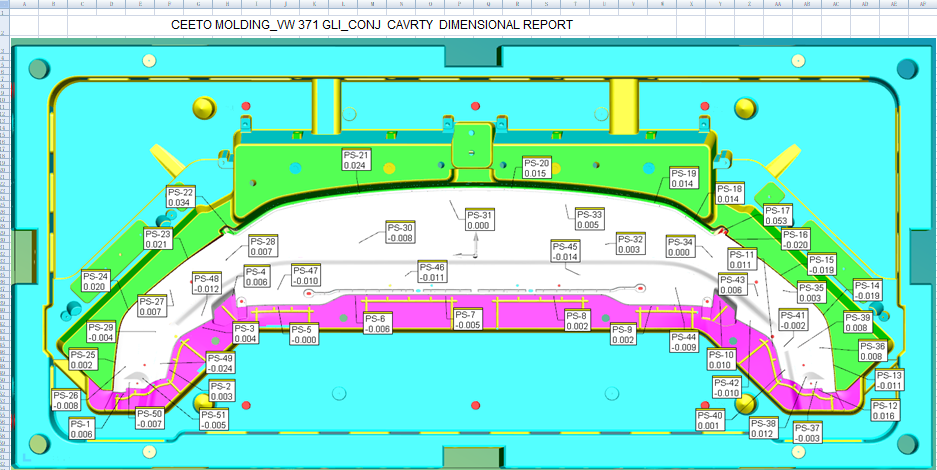

Quality Control to Flower Pot Plastic Mould

Here is an example of mould CMM report for cavity:

FAQ:

Q1: How long does a quotation take?

A1: In most cases, we respond within a couple of days of receiving an RFQ. However, there may be situations when we must source material from an external supply and therefore the quotation may be delayed accordingly.

Q2: What is the difference between a multi-cavity mold and a family mold?

A2: A multi-cavity mold has multiple cavities of the same part; a family mold produces a set. For instance, for an electronic enclosure, you may need a front, back, battery door, and a button. Those could all be molded at once in a family mold.

Q3: How long does it take to build a Plastic Garden Planter Mold?

A3: It's about 40 days for buying mould steel blocks to the first mould tryout, it means that 40 days from mould design approval to the first shot.

Q4: Can I modify the mold after the first run?

A4: We can modify our steel molds by additional machining, fill-in welding, welding in additional material, or inserting a replacement feature, for a reasonable cost. If the changes are too great, however, producing a new mold may be more cost-effective than reworking the existing one.