Payment Type:L/C,T/T,D/P,D/A,Paypal

Incoterm:FOB,CFR,CIF,FCA,EXW,FAS,CPT,CIP,DEQ,DDP,DAF,DES,Express Delivery,DDU

Min. Order:1000 Set/Sets

Transportation:Ocean,Land,Air,Express

Port:Ningbo,Shanghai,Shenzhen

$1000-50000 /Set/Sets

Model No.: CT-10836

Brand: Ceeto

Place Of Origin: China

Forming Method: Plastic Injection Mould

Product Material: Plastic

Product: Household Product

Application: Car

Material: Aluminium

Demoulding: Automatic

Surface Treatment: Heat Treatment

Using Hardness: >HRC45

Average Wall Thickness: >3mm

Mould Life: 500,000-1,000,000 shots

Certification: CE

Customized: Customized

Condition: New

Packaging: Wooden box

Productivity: 500000shots/mold life

Transportation: Ocean,Land,Air,Express

Place of Origin: China

Supply Ability: 5000sets/month

Certificate: ISO

HS Code: 8480411000

Port: Ningbo,Shanghai,Shenzhen

Payment Type: L/C,T/T,D/P,D/A,Paypal

Incoterm: FOB,CFR,CIF,FCA,EXW,FAS,CPT,CIP,DEQ,DDP,DAF,DES,Express Delivery,DDU

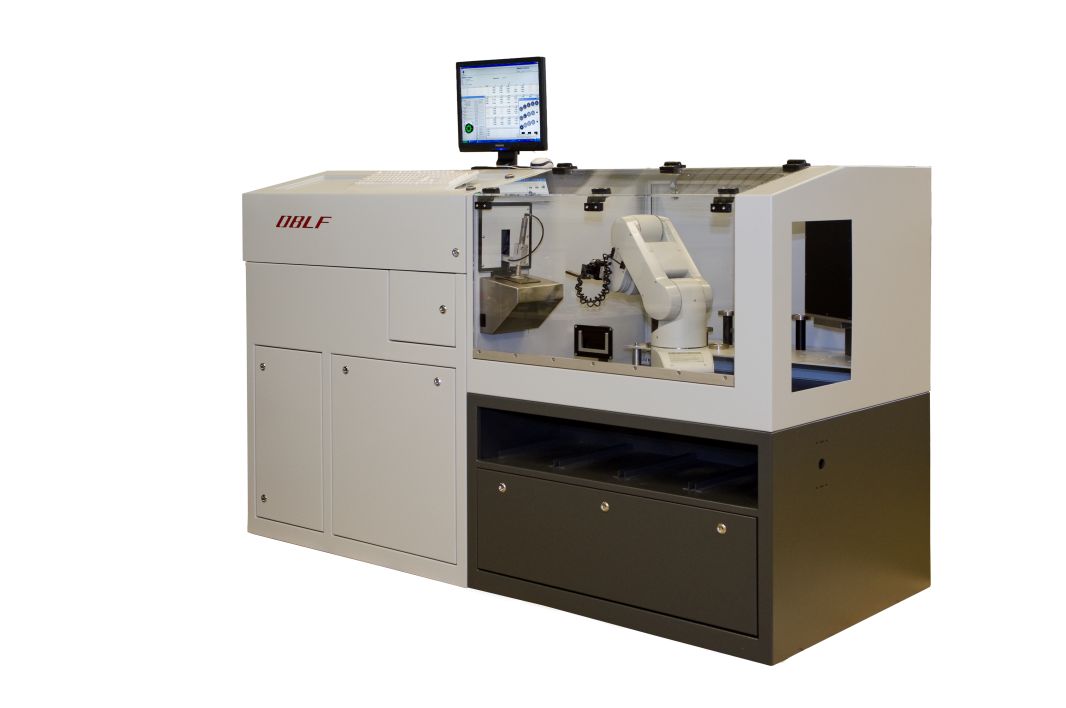

Automotive Components Die casting moulds that we supply are Automotive gearbox housing die casting product, silicone clutch housing die casting product, car reflector holder product and car cylinder block die casting product and new Automotive Double Clutch Variable Die Casting product.

Technical processing is a kind of method of casting liquid dies forging, a process completed in special die casting die to forge machine. Its basic technological process is: liquid metal is first filled into the mold cavity at low speed or high speed, and the mold has a movable cavity surface. With the cooling process of metal liquid, it is forged under pressure, which eliminates the shrinkage and porosity defects of the blank. It also makes the inner structure of the blank achieve the broken grain in forging state. The comprehensive mechanical properties of the blank have been greatly improved.

Basic information:

Our advantage:

The control of die-casting mould surface temperature is very important to the production of high-quality die-casting. Uneven or inappropriate die-casting temperature will also lead to the casting size instability, during the production process out of the casting deformation, resulting in thermal pressure, die, surface depression, internal shrinkage, and hot bubble defects. When the mold temperature varies greatly, the variables in the production cycle, such as filling time, cooling time and spraying time, are affected to different degrees.

Cold stripe: the reason is that temperature at the front end of the melt soup is too low and there are traces when stacking

Solution:

We sincerely welcome you to visit our factory, if you have any questions about Automotive Double Clutch Variable Die Casting Mould and Product, please contact us directly. We have been made a lot of die casting moulds and export to many countries hope we can be one of your engineering partners, we are looking forward to hearing from you. Thank you.